The recent US Geological Survey (USGS) study on seismic disruptions and their potential impact on the copper and rhenium industries has shed light on a crucial issue that could cost these sectors billions. The study underscores the importance of understanding and mitigating the risks associated with seismic activities in regions critical for copper and rhenium production.

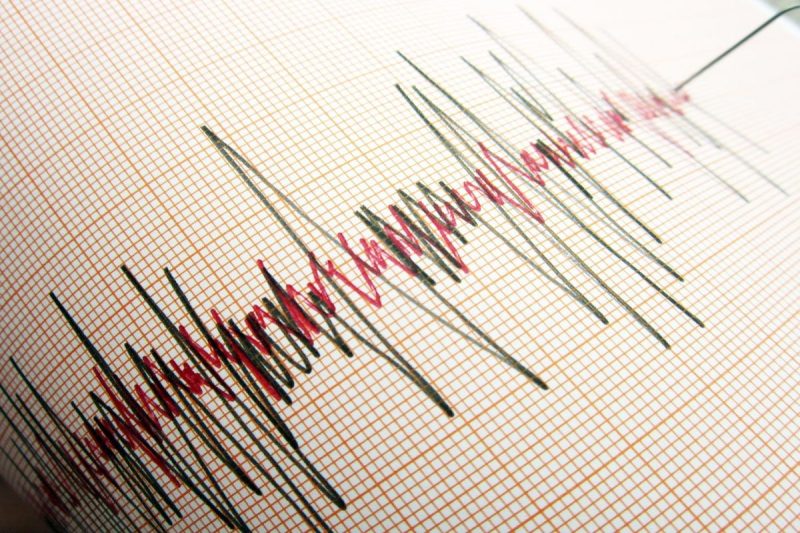

Seismic disruptions are geological events caused by the sudden release of energy in the Earth’s crust, leading to earthquakes, ground shaking, and other related phenomena. These disruptions can have severe consequences, not only on human settlements but also on vital industries such as mining and mineral extraction.

Copper and rhenium are two essential metals with diverse industrial applications. Copper, known for its excellent conductivity and corrosion resistance, is widely used in electrical wiring, plumbing, and electronics. Rhenium, on the other hand, is a rare and valuable metal used in aerospace, electronics, and other high-tech industries due to its remarkable properties at high temperatures.

The USGS study reveals that regions with significant copper and rhenium deposits are prone to seismic activities, putting these industries at risk. Mining operations in these areas face the dual challenge of maintaining operational continuity while managing the potential impacts of seismic disruptions.

In the copper industry, seismic disruptions can result in damage to infrastructure, disruption of supply chains, and loss of production. The USGS study estimates that a major earthquake in a key copper-producing region could lead to significant financial losses running into billions of dollars. Such disruptions could also have broader implications for the global copper market, affecting prices and supply dynamics.

Similarly, the rhenium industry could face severe consequences from seismic disruptions, given the metal’s rarity and strategic importance in high-tech applications. The USGS study highlights the vulnerability of rhenium supply chains to seismic risks and underscores the need for proactive measures to safeguard production and distribution networks.

Mitigating the risks associated with seismic disruptions in copper and rhenium mining requires a multi-faceted approach. Enhanced monitoring and early warning systems can help mining companies prepare for potential seismic events and ensure the safety of personnel and infrastructure. Investing in resilient design and retrofitting of mining facilities can also minimize the impact of earthquakes on production operations.

Furthermore, collaboration between industry stakeholders, government agencies, and research institutions is essential to develop comprehensive risk management strategies for the copper and rhenium industries. By sharing best practices, conducting joint research, and implementing robust contingency plans, the sector can build resilience against seismic disruptions and safeguard its long-term sustainability.

In conclusion, the USGS study serves as a wake-up call for the copper and rhenium industries to address the risks posed by seismic disruptions effectively. By taking proactive measures, enhancing preparedness, and fostering collaboration, these sectors can mitigate the potential financial and operational impacts of earthquakes and ensure the continued supply of these critical metals to meet global demand.